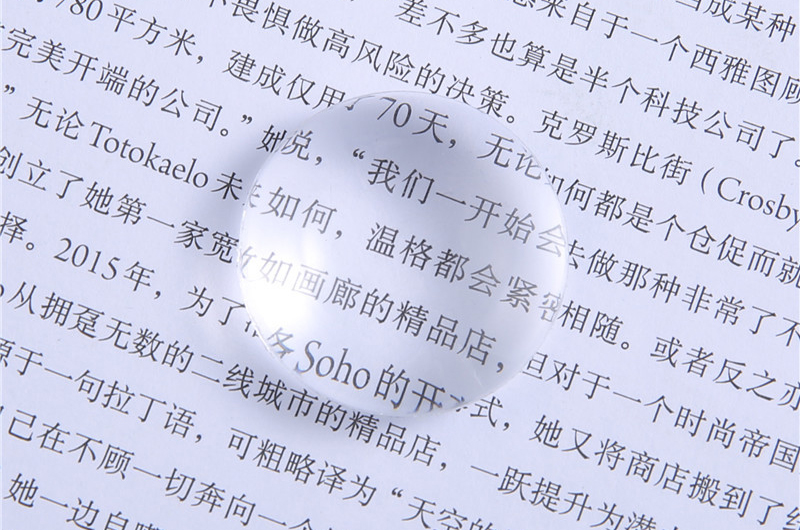

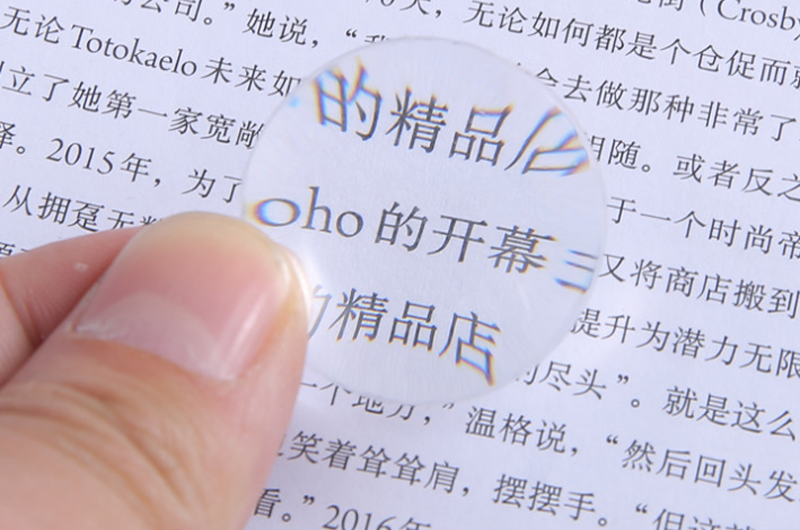

Ilensi ye-Acrylic, i-PMMA Ilensi yePlastiki.

Intshayelelo yeLens:

Isiseko seplate ye-acrylic lens yenziwe nge-PMMA, ebizwa ngokuba yi-pressed acrylic lens ngabantu baseHong Kong naseTaiwan.I-Acrylic lens ibhekisela kwipleyiti ye-acrylic ekhutshiweyo.Ukuze ufezekise i-electroplating ye-optical grade, i-plate yesiseko iya kwenza umphumo wesibuko emva kokugquma kwe-vacuum.I-lens yeplastiki isetyenziselwa ukubuyisela i-lens yeglasi, enenzuzo yobunzima bokukhanya, akukho lula ukuphuka, ukubumba okufanelekileyo kunye nokucubungula, ukufaka imibala ngokulula njalo njalo, ukuqhubela phambili kophuhliso kunyuka imihla ngemihla, kwaye kuye kwaba luhlobo lwetekhnoloji. kwimveliso yelensi.Iipleyiti zeplastiki zingenziwa ngokubanzi: isibuko esisecaleni, isibuko esinamacala amabini, isibuko seplastiki, isibuko sephepha, i-lens yesiqingatha, njl njl. zingenziwa ngokweemfuno ezahlukeneyo.Umzekelo, isikrini sefowuni ephathwayo kunye neTV inokubonwa yonke imihla.

Iimpawu zeLens:

I-Acrylic ilungele ukusetyenzwa okwesibini, njengokubumba, ukubumba kwe-thermoplastic, ukubunjwa kokuvuthela, i-blister, i-solvent bonding, ukuprintwa kwe-thermal, ukuprintwa kwesikrini kunye ne-vacuum electroplating.Emva kwempumelelo, yinto esiyibiza ngokuba yi-acrylic lens.

Ipleyiti ye-Acrylic i-polymerized yi-methyl methacrylate monomer (MMA), eyile polymethylmethacrylate (PMMA) iplexiglass yepleyiti, eluhlobo lweplexiglass ecutshungulwa yinkqubo ekhethekileyo.Inegama elithi "uKumkanikazi weplastiki".Uphando kunye nophuhliso lwe-acrylic lunembali engaphezu kweminyaka eyi-100.

Ukusetyenziswa kweLens:

I-Acrylic ineenzuzo zobunzima bokukhanya, ixabiso eliphantsi kunye nokubumba okulula.Iindlela zayo zokubumba ziquka ukuphosa, ukubunjwa kwe-injection, i-machining, i-acrylic thermoforming, njl. Ngokukodwa, ukubunjwa kwenaliti kunokuveliswa ngobuninzi, kunye nenkqubo elula kunye neendleko eziphantsi.Ngoko ke, isetyenziswa ngokubanzi kwiindawo zesixhobo, izibane zemoto, iilensi zamehlo, imibhobho ecacileyo njalo njalo.

I-Acrylic yeyona nto intsha ilungileyo yokwenza iimpahla zococeko emva kweekeramics.Xa kuthelekiswa nezinto ze-ceramic zendabuko, i-acrylic ayinayo kuphela ukukhanya okuphezulu okungenakulinganiswa, kodwa ineenzuzo ezilandelayo: ukuqina okulungileyo kwaye akukho lula ukulimaza;Ukubuyisela okunamandla, okoko nje i-foam ethambileyo efakwe kwi-toothpaste inokosula into entsha yococeko.Ubume buthambile, kwaye akukho mvakalelo yokuphola kwethambo ebusika;Imibala eqaqambileyo inokuhlangabezana nokusukelana nokuthanda izinto ezahlukeneyo.Isitya setafile, ibhafu kunye nendlu yangasese eyenziwe nge-acrylic ayikona nje ukugqwesa kwisitayela, iqinile, kodwa ihambelana nokusingqongileyo.Umzila wayo wemitha uphantse ufane nowamathambo abantu.I-Acrylic sanitaryware yaqala ukuvela e-United States kwaye ngoku yenza ngaphezu kwe-70% yemarike yamazwe ngamazwe.Ngenxa yobunzima kunye neendleko eziphezulu zemveliso ye-acrylic, kukho izinto ezininzi ezithatha indawo yexabiso eliphantsi kwimarike.Ezi zibambela, ezikwabizwa ngokuba “zi-acrylic”, ziyibhodi eqhelekileyo yendalo okanye ibhodi edibeneyo (ekwaziwa njengebhodi yesandwich).Ibhodi eqhelekileyo ye-organic iphoswe ngezinto eziqhelekileyo zokuqhekeka kwe-plexiglass kunye ne-pigment.Ubunzima bayo bomphezulu buphantsi kwaye kulula ukubuna.Isiphumo sokupholisa sibi emva kokupholisa ngesanti ecolekileyo.Ibhodi edibeneyo inomaleko obhityileyo we-acrylic phezu komhlaba kunye neplastiki ye-ABS embindini.Kulula ukucima ngenxa yempembelelo yokwandiswa kwe-thermal kunye nokunciphisa okubandayo ekusebenziseni.I-acrylic eyinyani kunye neyobuxoki inokuchongwa ukusuka kumbala ofihlakeleyo kunye nomphumo wokupolisha wecandelo leplate.1 Ukusetyenziswa kwezakhiwo: ifestile, umnyango wesandi kunye nefestile, ikhava yokukhanya kwemini, idokodo lomnxeba, isibuko sombala wokuhombisa, njl Upapasho lweSicelo: ibhokisi yokukhanya, ibhodi yophawu, ibhodi yomqondiso, i-rack show, njl. 4 Ukusetyenziswa kwezonyango: I-incubator yomntwana, izixhobo ezahlukeneyo zonyango, izinto ezingeyomntu: imisebenzi yezandla, izibuko zokuthambisa, izibiyeli, iiaquariums, izibuko zokudlala, njl. njl. i-reflector, i-acrylic reflector, njl.

Iimpawu zenkqubo:

1. I-Acrylic iqulethe i-polar side methyl, ene-hygroscopicity ebonakalayo.Ukufunxa amanzi ngokuqhelekileyo yi-0.3% - 0.4%.Kufuneka ibe yipleyiti ye-acrylic ngaphambi kokwenza

Kufuneka yomiswe phantsi kwemeko ye-80 ℃ - 85 ℃ ye-4-5h.2. I-Acrylic ineempawu ezisebenzayo nezicacileyo ezingezizo zeNewtonian kuluhlu lweqondo lokushisa lokubunjwa kokubumba.I-viscosity enyibilikayo iya kuncipha kakhulu ngokunyuka kwesantya sokucheba, kwaye i-viscosity yokunyibilika iphinda ichaphazeleke kakhulu kutshintsho lobushushu.Ke ngoko, ekusetyenzweni kokubumba i-polymethylmethacrylate, ukonyusa uxinzelelo lokubumba kunye nobushushu kunokunciphisa kakhulu i-viscosity enyibilikayo kwaye kufumaneke ulwelo olungcono.3. Iqondo lokushisa apho i-acrylic iqala ukuhamba malunga ne-160 ℃, kwaye iqondo lokushisa apho iqala ukubola liphezulu kune-270 ℃, kunye noluhlu olubanzi lweqondo lokushisa.4. I-viscosity ye-acrylic melt iphezulu, izinga lokupholisa likhawuleza, kwaye iimveliso zilula ukuvelisa uxinzelelo lwangaphakathi.Ngoko ke, iimeko zenkqubo zilawulwa ngokungqongqo ngexesha lokubumba, kwaye iimveliso zifuna kwakhona unyango emva kokubumba.5. I-Acrylic i-polymer ye-amorphous kunye ne-shrinkage encinci kunye noluhlu lwayo oluguquguqukayo, ngokubanzi malunga ne-0.5% - 0.8%, ehambelana nokwenza iiplastiki zeplastiki ngokuchaneka okuphezulu kwe-dimensional.6. Ukusebenza kwe-Acrylic cutter kuhle kakhulu, kwaye iphrofayili yayo inokucocwa ngokulula kwiisayizi ezahlukeneyo ezifunekayo.

Itekhnoloji yokucubungula:

I-Acrylic inokwamkela ukuphosa, ukubumba inaliti, i-extrusion, i-thermoforming, i-laser engraving, ukusika i-laser kunye nezinye iinkqubo.

Ukubumba ukubumba

Ukubumba ukubunjwa kusetyenziselwa ukwenza iiprofayili ezifana neepleyiti ze-plexiglass kunye nemivalo, oko kukuthi, iiprofayili zenziwe ngobuninzi bepolymerization.Iimveliso eziphosiweyo zifuna unyango emva konyango.Iimeko zasemva konyango kukugcina ubushushu kwi-2h kwi-60 ℃ kunye nokugcinwa kobushushu kwi-2h kwi-120 ℃.

Isitofu sokubumba

Isitofu sokubumba yamkela izinto zegranular ezilungiselelwe ngokunqunyanyiswa kwepolymerization, kwaye ukubunjwa kuqhutyelwa kwi-plunger eqhelekileyo okanye umatshini wokubumba isijija.Itheyibhile 1 ibonisa iimeko eziqhelekileyo zenkqubo ye-polymethylmethacrylate injection molding.Inkqubo iparameters Screw umatshini wokubumba umatshini wokubumba umbhobho womatshini wokubumba umbhobho ℃ ubushushu obungasemva 180-200 180-200 phakathi 190-230 ngaphambili 180-210 210-240 iqondo lobushushu lombhobho ℃ 180-210 210-240 inaliti yokungunda 4-80 ℃ 4 ℃ 180-240 ℃ uxinzelelo MPa 80-120 80-130 ebambe uxinzelelo MPa 40-60 40-60 screw speed rp.m-1 20-30 naliti iimveliso kufuneka kwakhona emva unyango ukuphelisa uxinzelelo lwangaphakathi, Unyango luqhutywa kwi 70-80 ℃ ukujikeleza komoya oshushu owomisa i-oveni.Ixesha lonyango lwe-acrylic bar ngokubanzi lithatha malunga ne-4H ngokuxhomekeke kubukhulu bemveliso.

Thermoforming

I-Thermoforming yinkqubo yokwenza ipleyiti yeplexi okanye iphepha libe yimveliso yobukhulu obahlukeneyo kunye neemilo.Ukusikwa okungenanto kubukhulu obufunekayo bunyanzeliswa kwisakhelo sokubumba, sitshiswe ukuze sithambe, kwaye emva koko sixinzelelwe ukuba sisondeze kumphezulu wokubumba ukuze sifumane ubume obufanayo nomphezulu wokubumba.Emva kokupholisa kunye nokubunjwa, umphetho unqunywe ukufumana imveliso.Indlela yokudweba i-vacuum okanye i-pressurization ngokuthe ngqo ye-punch kunye neprofayili ingamkelwa kwi-pressurization.Iqondo lokushisa le-thermoforming lingabhekisela kuluhlu lweqondo lokushisa olucetyiswayo kwiThebhile 3. Xa usebenzisa i-vacuum ephantsi yokwenziwa kweemveliso eziqulunqiweyo, kuyafaneleka ukwamkela ubushushu obusondeleyo kumda ophantsi.Xa usenza iimveliso ezizinzile ezinzulu ezinemilo enzima, kuyafaneleka ukwamkela ubushushu obusondeleyo kumda ophezulu.Ngokuqhelekileyo, iqondo lokushisa eliqhelekileyo liyamkelwa.

Sinazo zonke iisayizi ze-Arylic lens, ukuba uyazifuna, nceda uqhagamshelane nathi ngobubele, sinako ukwenza ilensi ye-Arylic ngokwemfuno yakho.Ungathumela umzobo kuthi, emva koko, sinokukwenzela iimolds.Enkosi kakhulu.